Cigar Story

While hunting down a fraudster in the Dominican Republic, the editors had a chance to visit a cigar factory. Our host was Jose Tomas Dominguez, the Master Blender and Director General of Tabacalera Victor Sinclair S.A. We have used the word host for a reason, as at all times he focused on sharing his facility with us, introducing us to the craftsmen, and he clearly enjoyed showing us what they are able to make.

The reason ÆGIS journal is dedicating this article to this cigar maker is because we saw, in a discrete location and industry, a manger/owner who “gets it”. He understands feed forward controls such as due diligence, asset protection, OPSEC; as well as feed back controls such as competitive intelligence, IPCI protection, and brand defenses, and integrates them while managing a large and very dynamic operation. We asked if we could use our experience touring his facility and the experiences he shared with us as the subject for a full i l d d issue of the ÆGIS journal, showcasing an owner/manager who both runs his business and deals with these issues. Sr. Dominguez agreed, but with the right to preview the article and edit any sensitive material that might disclose his methods. We agreed on the spot, since this is an example of a feed forward control.

The reason ÆGIS journal is dedicating this article to this cigar maker is because we saw, in a discrete location and industry, a manger/owner who “gets it”. He understands feed forward controls such as due diligence, asset protection, OPSEC; as well as feed back controls such as competitive intelligence, IPCI protection, and brand defenses, and integrates them while managing a large and very dynamic operation. We asked if we could use our experience touring his facility and the experiences he shared with us as the subject for a full i l d d issue of the ÆGIS journal, showcasing an owner/manager who both runs his business and deals with these issues. Sr. Dominguez agreed, but with the right to preview the article and edit any sensitive material that might disclose his methods. We agreed on the spot, since this is an example of a feed forward control.

ÆGIS: Sr. Dominguez what is the most important aspect of your cigar operation?

Raw material and people. Everything else such as brands, images, et cetera is built upon those two items.

For the raw material we need tobacco, we need good quality tobacco grown under conditions we know. To that end, we contract with a number of farmers in the Dominica Republic and elsewhere to grow tobacco for us each every year to help us achieve consistent quality and improve our understanding of the tobacco we use. I am using two terms together for a reason, consistent quality and understanding. Many farmers in the DR grow excellent tobacco, but not all are consistent in their quality and methods year to year. The consistency of the farmers with whom we work provides us excellent quality, but also a tobacco we know. It is much like wines from a specific vintner with constant flavors and tannins you come to expect. With these farmers we come to know the tobacco leaf and how it will age and taste – one to five years later.

I personally go through tons of samples, looking for just the right tobacco, for the different cigars we make. I work directly with the rollers and the factory management to ensure we are all doing our best.

The people are the second key ingredient. I know most of our workers by their name, and know their families. Many have been with us for years and years; others have come to us recently, as we continue to grow. They are given great freedoms in their work and they have taken on great responsibilities. They have a freedom to work, within reason, when they want to work. The responsibilities they assume are those of making premium hand rolled cigars. This freedom and responsibility has also bread an interesting culture of innovation. Many different cigars we make today, and how we present these cigars, began as an innovation of my people. I am very paternalistic, these are my people.

This has lead to some great successes. It made us all feel great when a big, long established, and may I say prestigious cigar retailer, chose us as one of their manufacturing facilities for their private labeled cigars. They had toured many different factories in the DR and elsewhere and they chose us. Not me, us.

We are required to remain vigilant of the people and the process. Even if for no other reasons than to secure the time and years invested in our people, our facilities, and our brands. It cannot take less than 2 years to launch a brand and probably no less than 5 years to have it become established. A well recognized brand will sell at a considerable premium to an unknown or tarnished brand.

ÆGIS: Sr. Dominguez, how do you protect what you do here, for blending and innovation, and at the same time continue to do your research on others? Ah, I think in our business the question is “How do I keep our ideas about the future to ourselves?” The second question is “What do I know about – the others?”

The truth is that very little is not already known by all of the other makers of cigars. Not just in the DR, but all over the world. What is not widely known is how much we are buying in tobacco, and the grades, as well as who we are planning to sell or what we are doing with our brands. Obviously once we begin selling, launch a new brand or update an old band – everyone knows. But if we keep our development process private it still gives us from six months to a one year jump on the competition. We keep these plans about the future, how you say “hush – hush”. Since our growth and product cycle is based upon crop cycles, an aging and fermenting process for the leaf and then, only then manufacturing, we must plan well in advance. And this planning and what we are doing is known to only a very few — a select few who know how much tobacco we have agreed to purchase and from which farmers. There is no advance paper trail on what we buy from the farmers, we do this on a hand shake and our reputations. As for our marketing ideas and branding exercises – even fewer know about this, mostly it is myself with a few other insiders.

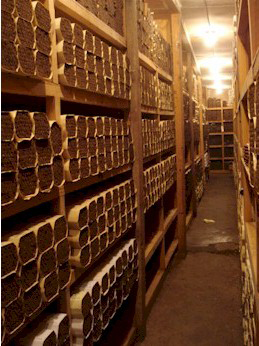

You see by controlling all aspects of the cigar making process very little information can leak out. Not only do we make our own cigars, we make our own boxes and labels. There are almost no vendors of outside finished goods that we incorporate into what we make and sell.

As for how do I know what the others are doing, sometimes I learn from industry gatherings, sometimes suppliers gossiping, etc… There is no organized operation for Competitive Intelligence, except for I buy and try every new cigar I find or my people find in the US,Europe or in the DR – every one. Then I try to figure out who is making it and how they made this cigar I am trying.

It was doing this and I learned of both the popularity and mostly awful small machine made flavored cigars. This was part of the inspiration for the work we did toward the development of the Honey Delight ™ series. These small cigars, or cigarillo, are a good simple smoke that is just the right size and flavor for the moment. These have been very popular.

ÆGIS: Do you ever feel threatened being a successful man in Latin America?

Not really. I live my business with my people. While I have a good sized operation, all of my profits, if you will, have been put back into the business. I live in a nice apartment but it is neither big nor fancy. It is just right for me and my family. I am not a target of mischief in the DR. I have more problems with the complex and litigation happy system in theU.S.than I have problems here in the DR.

The real problems come with travel and the many places I visit in the US, Europe, Canada, etc… I am the ambassador of my company and my people. I must look good and always be ready for anything from protected business negotiations to rich food and little sleep. I am not sure I am always very good at this portion of my position. The travel is a blessing to get to meet and see so many of our customers, but I do so prefer to be home and here (the factory).

ÆGIS: What technical issues do you face in your business?

Too many. We track the buying of the tobacco leaves and the fermenting process. We track the volume and quality of each of our rollers. We monitor the waste material from the production process. All of this goes into monitoring the process.

As an art form, the making of a fine cigar is more regulated than even alcohol. We must be aware of our pricing and the impact of excise tax on all of our products. Different countries levy taxes based upon the number of cigars, the weight of the cigars, the boxes of cigars, etc… We have to work closely with the many different importers and distributors of our cigars to ensure our products clear customs quickly. Cigars left sitting on a dock or a warehouse for two or three months uncared for are a loss. They could no longer be sold after such a delay. This is in addition to applying for and getting export licenses, import licenses, filing reports and paying taxes over and above duties.

As an art form, the making of a fine cigar is more regulated than even alcohol. We must be aware of our pricing and the impact of excise tax on all of our products. Different countries levy taxes based upon the number of cigars, the weight of the cigars, the boxes of cigars, etc… We have to work closely with the many different importers and distributors of our cigars to ensure our products clear customs quickly. Cigars left sitting on a dock or a warehouse for two or three months uncared for are a loss. They could no longer be sold after such a delay. This is in addition to applying for and getting export licenses, import licenses, filing reports and paying taxes over and above duties.

We also protect our intellectual property. We register our brands and trademarks in the US and inEurope and vigorously defend our intellectual territory.

I have been working computerizing the process but that too has hurdles. Some of it makes sense to do so, but so many of the inputs have to be generated by hand before it can all be assembled and analyzed.

ÆGIS: Sr. Dominguez tell us some of your experiences and stories from running your business — the events and challenges you have faced.

The cigar business is filled with stories and legends. I guess I need to stick to the stories, I am not old enough for any legend business.

I was in Miami and had concluded my days work. I saw a small cigar shop in South Beach, they are all over the place. The cigars shops in Miami are wonderful, all decorated with neon signs in the window and very knowledgeable people behind the counter. It’s a wonderful cultural thing inMiami. I went into one of these shops in South Beach and found some of my product. I purchased a few cigars of mine and a few of other manufacturers. As I walked outside the store I lit up one of my favorite cigars from Victor Sinclair. It was horrible and I was furious. This grassy cardboard things is not what we put out. I called home from my cell phone while I was standing on the corner in font of the small cigar shop looking at this burning thing in my hand. I called the managers at home, I called the supervisors at home, and while I was ranting about quality a quiet voice in my head said – look at the cigar – look closer. It had our band on the cigar, it was shaped like our cigars, but it was rolled differently and had a large vein in the wrapper. We de-vein our wrappers. It was not made by us. It took a few moments for it to sink in, but I was holding a counterfeit Victor Sinclair!

I was in Miami and had concluded my days work. I saw a small cigar shop in South Beach, they are all over the place. The cigars shops in Miami are wonderful, all decorated with neon signs in the window and very knowledgeable people behind the counter. It’s a wonderful cultural thing inMiami. I went into one of these shops in South Beach and found some of my product. I purchased a few cigars of mine and a few of other manufacturers. As I walked outside the store I lit up one of my favorite cigars from Victor Sinclair. It was horrible and I was furious. This grassy cardboard things is not what we put out. I called home from my cell phone while I was standing on the corner in font of the small cigar shop looking at this burning thing in my hand. I called the managers at home, I called the supervisors at home, and while I was ranting about quality a quiet voice in my head said – look at the cigar – look closer. It had our band on the cigar, it was shaped like our cigars, but it was rolled differently and had a large vein in the wrapper. We de-vein our wrappers. It was not made by us. It took a few moments for it to sink in, but I was holding a counterfeit Victor Sinclair!

It was the same realization process one goes though when you go to your car, and it is missing. You look all around for the car and it is nowhere to be found. Slowly, and reluctantly, you come to the conclusion you have lost your car – it has been stolen.

Sr. Dominguez testing a newly rolled cigar.

It was that same slow process I was going through, from anger to frustration, looking for what had happened to slowly coming to the conclusion that this thing in my hand was not one of our cigars – it was a counterfeit.

I suppose imitation is the best form of flattery and I must admit to being somewhat amused. My brand was now so well recognized that someone went through all of the effort to counterfeit our bands and packaging to sell cigars under out name. I guess it’s a sign that we are making it.

My solution to the problem was to calm down. A long walk helped. I then returned to the cigar store. I spoke to the owner of the store, and showed him my card. He was at first very excited but when I told him of my problem much of the luster of my visit disappeared. He showed me the boxes of cigars he was selling under our brands. To my relief, only one of the brands was counterfeit. I purchased all of those boxes at his retail so that he would not be out anything from this event. He supplied me with the name and address of the wholesaler who had sold him the cigars – this wholesaler was an excellent customer of ours. The wholesaler was a bit embarrassed when he told us he had purchased a “lot” of cigars from a liquidator of another cigar distributor that had gone out of business. Why did the other cigar wholesaler go out of business? It seems all they sold were counterfeit cigars.

Since this event we have stepped up our secret shopper programs and have developed certain security measures known only to us, to spot both fake cigars and fake boxes.

ÆGIS: One of our editors exercises regularly, eats properly and takes his vitamins. The other editor has thus had to pick up the slack.

We were given a gift of a sample box of the Victor Sinclair 55 series Cigars. The sampler box contained three cigars each of the Corojo, Maduro, Sun Grown and Camaroon style cigars. The Maduro cigars were shared by a local Vice Mayor, a 4 star Chef and this editor. The reviews were 100% “excellent cigar”. The three Sun Grown cigars were shared with fellow adventurers on a canoe trip down theColorado river from Hoover Dam to Willow beach. The fellow adventurers were both regular cigar smokers with some high brow tastes. Both of these gents really liked the cigar and saved the bands to buy at their local tobacconist. To top it off, a few women from another camp smelled the cigars and stopped by. From one of the women, “If my boyfriend’s cigars smelled this good, maybe he could have them more often.” Now that’s an endorsement. We are hoarding the Corojo and Camaroon for a future Adventure.